TQ Creates a Much Smaller, Lighter, Quieter E-Bike Drive System

Frankfurt, Germany

It’s a sign of how attractive the bicycle industry has become to outside players when a world leading company which already has 1,700 specialists working in robotics, aerospace and rocket science decides to invest heavily into developing new bicycle components.

Not only that, it then works secretly for four long years with one of the world’s leading bicycle brands, Trek, to develop an entirely new drive system for an entirely new carbon frame platform, before publicly launching it at Eurobike 2022.

The company is TQ, and representative Roman Stutzer offered some background when the Micromobility Report visited TQ’s booth at Eurobike.

“Our company is family owned and was founded in 1994. TQ stands for ‘technology and quality’,” Roman explained.

“We’re a German company based in Bavaria, near Munich. We’ve been doing electronics development for nearly 30 years now. You can find TQ electronics in Airbus aircraft.

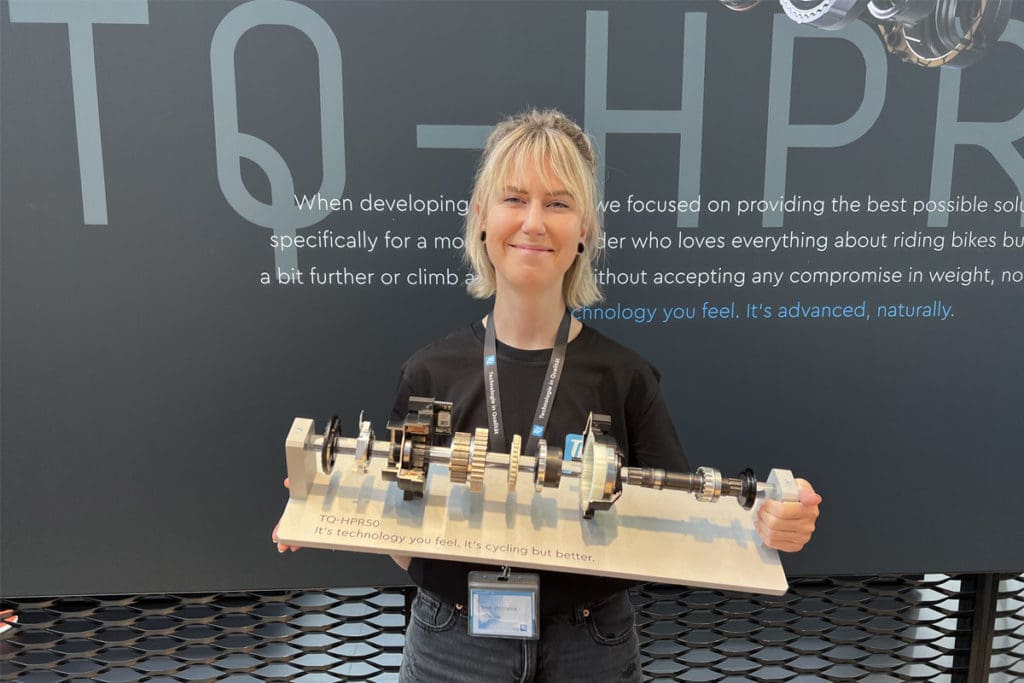

TQ Product Marketing Manager Anna Vodickova continued: “We met Trek in 2018 at Eurobike. Their product engineers were aware of our technology. It comes originally from robotics applications.

“TQ is split according to products, with one centred around drive systems for robotics, e-bikes, medical applications, Mars rovers and things like this,” Anna said in a most matter-of-fact way as though everyone is making a Mars rover these days. In fact, upon querying if I heard this correctly, she said: “Yeah, we developed this together with the German aerospace centre about 18 years ago.

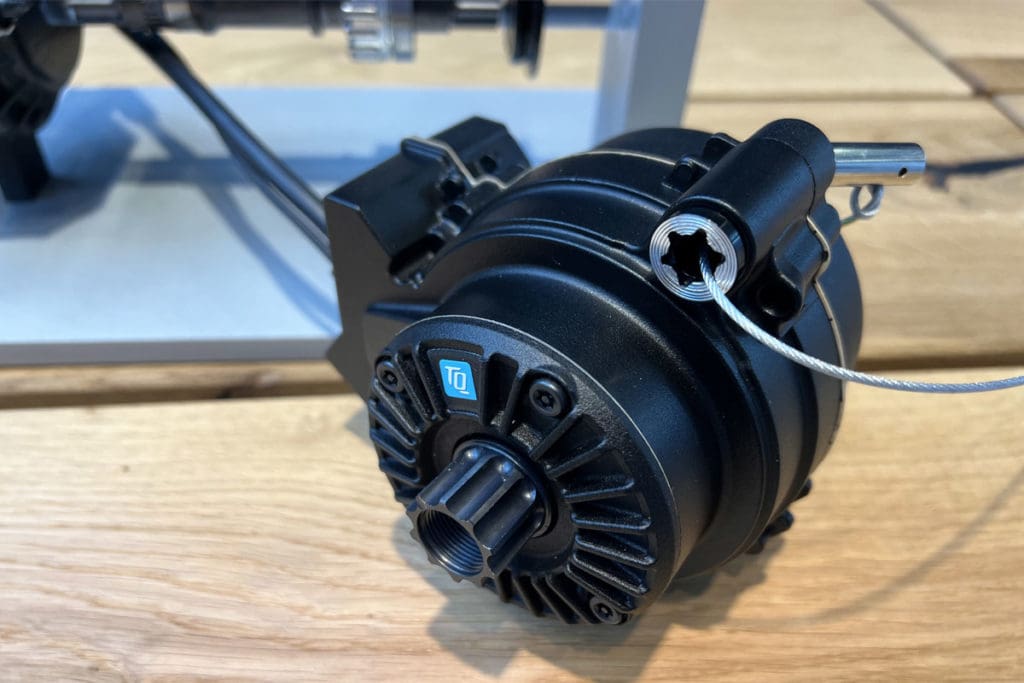

“We are further developing and innovating our frameless motors. They have the highest torque density on the market and they’re pretty much indestructible – really pushing the boundaries of limits for use in space.

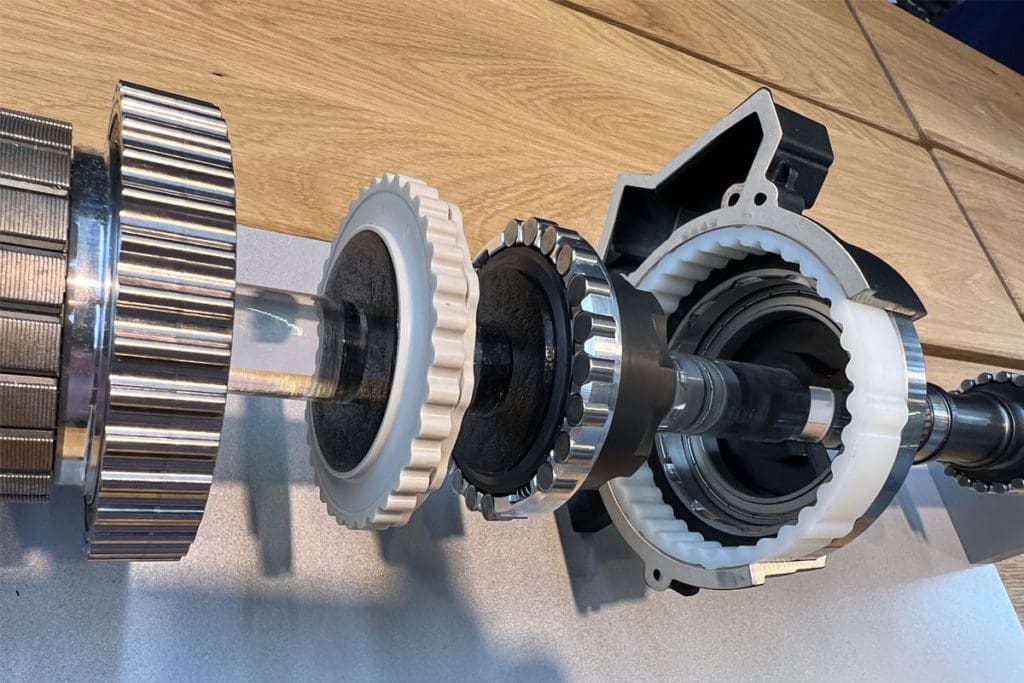

“We use a harmonic pin-ring transmission which rotates off centre. It’s a different kind of transmission to what usual e-bike drive units use. The rider’s cadence is much slower than an electric motor. Electric motors usually work much better at higher speeds.

“With normal cog wheel motors, you need multiple layers of cogs to reduce the motor speed to the rider’s cadence. With harmonic pin-ring transmission, we’re able to do that in one step.

“With cog wheels you only have a few teeth engaging at any one time. Which means you have a lot of material not being used. It also causes friction, lag, noise, wear and tear. We’re able to simplify this. Most of the teeth in our double teeth ring are always engaged.”

This is really difficult to explain in words but easier with a video. If you watch this TQ video, which runs for almost two minutes, the really enlightening part is just seven seconds of the video from 1:03 to 1:10 showing a computer graphic animation of how the drive works.

A key advantage of TQ’s system is how much it reduces the motor speed down in a single step – by a ratio of 17.5:1 to be exact. In other words, if the rider is pedalling with a typical cadence of 100 revs per minute (rpm), the motor would be spinning at 1,750 rpm.

According to Roman, ‘traditional’ e-bike drive systems, including the Bosch system used by many bike manufacturers, have a reduction ration of about 5:1 or 6:1, so their motor has to spin about three times slower than the TQ motor. They therefore need to be larger and more robust.

Anna said TQ also has an advantage with its electronics.

“All the control boards are made in-house, so we communicate very closely. Our production is in-house as well,” she said.

“For example, we were capable of doing a compact battery with a smaller control board, the size of a business card. Most control boards run the length of the battery pack.”

Anna was very diplomatic when asked the obvious question of when other bike brands would get access to TQ’s e-bike drive system technology.

“Right now, we’re focused on Trek as our exclusive partner,” was all she said.

However, if their elaborate expo booth, complete with enclosed offices for private meetings, was any indication, TQ wasn’t just at Eurobike to show their new drive to the media and public. Perhaps we’ll see new announcements at next year’s Eurobike.