Huge Investment in New Products on Show at Eurobike 2024

Frankfurt, Germany

Each year, Frankfurt, Germany hosts the world’s biggest bicycle and micromobility expo. With western Europe being so much more transport and utility focused than Australia, products that still have a small market here, such as e-cargo bikes, have huge markets in Europe, so take centre stage at Eurobike.

This article is a customised version of an earlier Eurobike report that we previously published in our trade newsletter, The Latz Report.

By the numbers Eurobike was a record breaking show. There were 35,080 trade visitors from around the world, plus 33,090 public visitors. Both of these numbers were up slightly on last year. They came to see over 1,800 exhibits, which ranged from small booths up to massive displays of 1,000 square meters in size. The total show covered 150,000 square metres of indoor and outdoor exhibit space. Plus several test tracks that were longer and better organised than when I attended the first Frankfurt edition of Eurobike, two years ago.

Vast Array of New Products

As you can imagine, just about every exhibitor has at least one new product. Below you’ll find photos and short stories about some of these. It’s always a challenge to decide what to highlight. My criteria is that new products have to be innovative with potential to become widely sold, even if in some cases that might be years into the future.

Please enjoy and feel free to make comments in the area at the bottom of this article about which products you think might get a solid foothold in the marketplace and which are duds!

Buffalo Bike

This new product will probably never be available for sale in Australia but won a Eurobike Gold Design Award and will have a huge impact on many lives.

Over the past two decades, World Bicycle Relief has already made and distributed about three quarters of a million Buffalo bikes, mainly in Africa. Bullet proof strength, reliability and simplicity are essential requirements so until now, they’ve all been single speeds with back pedal brakes.

This is their new Buffalo Utility S2 which stands for “Speed Two”. A fragile, complex derailleur gear system or expensive internal hub gear was not the best option for the extreme workloads on remote, dusty tracks that these bikes face, so they designed this two chain, two gear solution where the gears are changed up or down through a quick part-revolution back-rotation of the pedals.

Because you can’t move the hub axle to optimise chain tension for each chain, they had to work out an exact combination of chainring and rear cog sizes that gave the same tension for both chains. This resulted in one of the rear cogs being one tooth larger than the other.

It also meant changing to rim brakes, which in turn meant moving away from steel rims to alloy to provide better braking surfaces.

Burley

Burley is an Oregon, USA brand that has been creating bike trailers for decades and has also been distributed in Australia for most of that time through to today.

Here President of Burley, Allison Straub is showing their new Hopper model.

It can quickly convert between bike trailer and walking stroller, has a weight capacity of 45kg and is made from recycled fabric.

The hopper will retail in Europe for €599 (A$934).

Schwalbe

Schwalbe’s new click valve was one of the smallest new products launched at Eurobike this year, but possibly the one that will sell in greatest numbers if it’s commercially successful.

After decades of virtually no change to the design of Schrader and presta bicycle valves, the click valve uses a spring loaded ring mechanism to create a better seal between the valve and the pump. It can screw into existing valves. Meanwhile existing pumps can use the new system through use of an adaptor.

Schwalbe says the benefits are allowing 50% more airflow and no pressure loss. The click valve won a Eurobike design award.

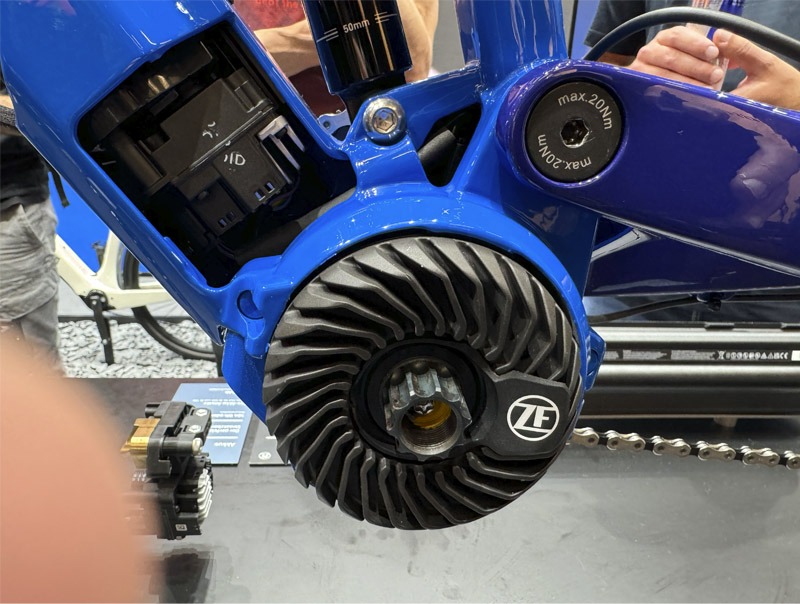

ZF

You might not have heard of ZF, but you will have heard of the car companies for with they’ve been making transmissions and other parts for over a century, including Mercedes Benz.

ZF has over 160,000 employees worldwide and annual sales of over A$70 billion, so when they quietly entered the e-bike drivetrain market in 2020 with a fairly basic product mainly aimed at the cargo bike market, you knew that they’d be playing the long game, with more products to come.

This year they launched their new Centrix drive unit. This photo shows a cut-away sample frame so you can see the controller that connects the internal down tube battery to the motor.

The Centrix can be software controlled to deliver either 75 or 90 nm (newton metres) of torque. It uses a ‘wave gear’ system to reduce the motor speed by a ratio of 50 to 1. This is a far higher reduction ratio than other brands offer, which allows the motor to spin faster for any given bicycle speed. The motor weighs 2.5 kg.

The Centrix has been spec’d by several bicycle brands across France, Germany and Switzerland.

Optibelt

Relatively few bikes are sold with belt drives in Australia, but it’s a growing trend because they’re particularly well suited to e-bikes.

USA manufacturer Gates has dominated the bicycle belt drive market for decades after expanding from their customer of Harley Davidson motorcycles. Gates is a century old global company with over 15,000 employees, headquartered in Denver, Colorado.

But now an even older company, 152 year old Optibelt from Germany, who makes belts for Porsche and others, has entered the bicycle industry. So far their belts are only on three bike brands, but Optibelt say they’re in discussions with 25 others.

Optibelt say they have a different fibre content that allows better flexibility than Gates, letting them go down to a 16 tooth rear cog compared to the 19 tooth minimum for Gates. The two systems are not compatible, with Optibelt using a 14 mm pitch vs 11 mm for the Gates belts.

Circular Logistics

Even the humble bicycle box has a new technology competitor. This is Matthias Hofer, co-founder of Circular Logistics.

Their new bicycle box is made from polypropylene. Matthias says that if it’s looked after it can be re-used as many as 20 times before it can then be recycled.

Clearly this requires shipping empty boxes back to the manufacturer for re-use, which would be more expensive and problematic in Australia, where manufacturers are thousands of kilometres away overseas, compared to in Germany where the manufacturer might be a short drive away.

The box is about 2kg heavier than a conventional cardboard bike box.

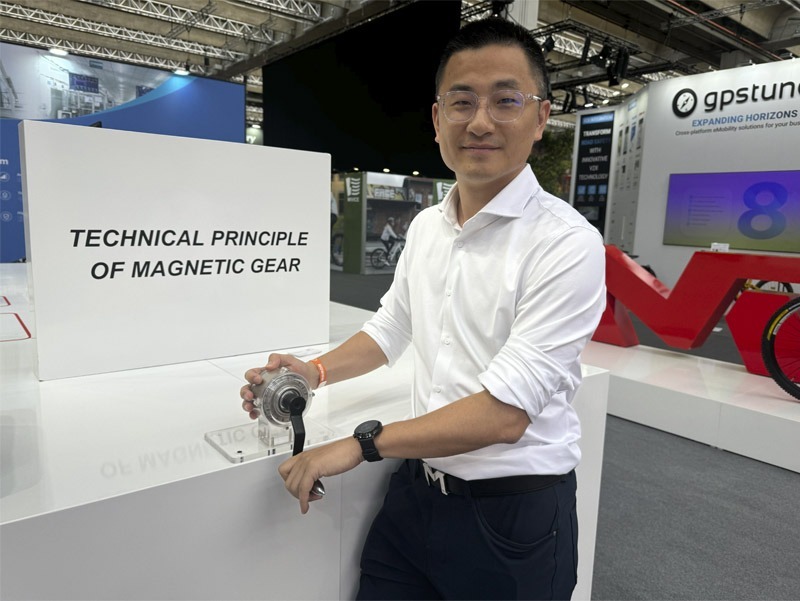

MGM

This is Zhi Pon, Vice President of Sales and Drive System Department Manager for MGM with is a Chinese company that has developed a contactless magnetic drive system.

The problem they’re trying to solve in a better way is how to reduce the fast spinning e-bike electric motor speed down to one necessary to drive a bicycle wheel.

Zhi says that all of the current systems have more power loss than his new system, plus other compromises. Metal planetary gears are strong, but noisy. Plastic gears are quieter, but not as durable and harmonic gears are less power efficient.

He said that their system has no mechanical drive linkage at all, but is electro magnetic. He said that this is 20 year old technology, but very difficult to manufacture and slightly more expensive. In return it offers better durability, less power loss and is quieter.

He says their company, which has about 1,200 staff and was launched 40 years ago is already the biggest throttle company in the world for e-bikes.

Seeing Around Corners

There were at least two different solutions on display at Eurobike for bike lights that help you see around corners, one mechanical, one electronic.

The first, from Monkey Link involved attaching the light to the steerer tube, inside the head tube and then having a clear window in the head tube so that the light could shine through, always pointed in exactly the same direction as the bike was heading.

The second, from Busch + Muller was an electronic system that sensed the angle and direction of the handlebars and added more slivers of light in that direction. It would be easier to explain with a video, but if you look closely at the light in this photo, you’ll see two extra areas of light to the left. This was when the bars were turned left. Straight ahead you only get the centre section. Turn right and you progressively get one, then two extra light areas to the right.

They have models starting from 2,000 lumens up to 8,500 lumens. There’s an app that lets you customise the beam for the type of cycling you plan to do. All of this cutting edge tech comes at a price – €450 retail (A$697).

Aeron

The weight of this tiny product had to be felt to be truly appreciated – just over 20 grams for a road bike inner tube. If all of the claims made below prove to be true in real world use, then this tiny product could be one of the biggest new developments coming from this year’s Eurobike.

Logan van Bokel, is Global PR Manager for RTI Sports, a German company founded by Franc Arnold over 20 years ago. The company is best known for its Ergon range, that includes anatomic handlebar grips, saddles and other products, but at this year’s Eurobike they launched a new range of inner tubes that were far lighter and smaller than any traditional tubes.

Logan explained that they’re made from TPU which stands for thermoplastic polyurethane – in other words, plastic.

“Aeron is a brand new brand, completely dedicated to TPU inner tubes,” he said. “We have road, mountain bike, gravel, with three versions in each. Our superlight race is our lightest most compact. Extralight protect is more middle of the road and ultraprotect is our strongest, most durable tube. It’s about the weight of a conventional tube but six times more puncture resistant.

“The TPU engineering is the secret. Our manufacturing partner in Europe also makes tennis racket strings out of TPU, parts for your mobile phone…

“The air retention is very strong. Our extra light protect will be 5x to 10x better than a latex tube (of similar weight) and similar to what a well made butyl tube can do.

“These are prototypes, but our production tube valves will also be TPU.”

These tubes won’t be cheap, at €20 to €25 each, (A$31 to $39).

Retractable Cargo Bikes

In Europe in particular, where most people live in apartments and storage space is at a premium, the bulk of cargo bikes is a big problem when it comes to parking them at home. Although most Australians live in suburban homes, there’s also a huge boom in apartment construction here, particularly in the inner city areas where cargo bikes are probably more likely to be sold. Therefore, anything that can make cargo bikes smaller for storage will probably find willing customers.

There were at least two different solutions to this problem on display at Eurobike.

Cyclr

This Cyclr front loading cargo bike can be extended for use, then retracted for either storage, or for more nimble riding when you’re not carrying as much in the box.

This model is only prototype number two, so it’s not yet in production.

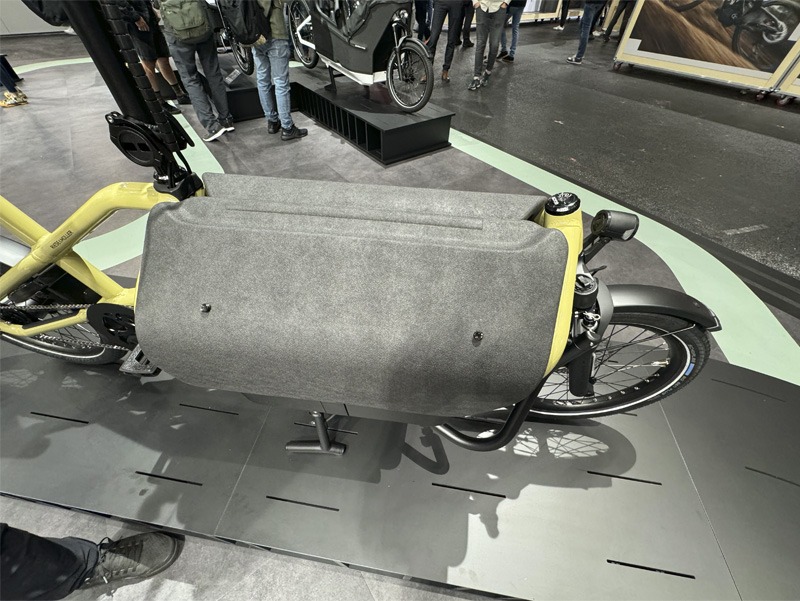

Riese & Muller

Meanwhile this Riese & Muller Carrie Vario literally takes a lateral approach. The front cargo section folds inwards for storage in tight spaces as well as an element of security and weather protection for whatever might still be stored inside. It then folds outwards to accommodate up to two children side by side.

RCYL

This RCYL bike is made from used commercial fishing nets which are first broken down to a granular size, then moulded to create the frame and some components.

DJI

Without doubt the “hottest” new product in the minds of the media and many attendees at Eurobike this year was this Amflow mountain bike. Not so much the bike as its Avinox drive system, which was the first public launch of DJI into the bicycle industry as a designer and manufacturer of e-bike drive systems.

If you haven’t heard of DJI, the company was founded in China in 2006 and is probably the best known high tech drone manufacturer in the world. The multibillion dollar company has clearly decided to invest heavily in the bike industry.

“We’ve been keeping it secret until we launched here,” said Olivier Monbon, Senior Communications Manager for DJI. “It’s not just a motor or battery, it’s a complete system. The motor is 2.52 kg and you can get 105 Nm of torque. We make it in house.”

“We have expertise with drones, cameras, stabilisation. We have mini drones that fit in the palm of your hand but can fly 10km away from you while you still have control.

“We’ve proved our batteries and brushless motors through billions of kilometres of drone flights. We’ve made the flight control systems feel like an extension of your body.

“All this experience, we want to apply to the bike industry, starting with the mountain bike. Why? Because we’re a tech brand for the outdoors.

“Of course, DJI is open to work with all the bike manufacturers. We’ve made a bike controller that has 42 sensors in the rear wheel. It has a gyroscope that knows if you’re riding up or down. It’s very smooth and intuitive.

“We’ve been working on the bike project for 3 ½ years. It’s a key project for DJI. It’s not just a little side project.

“Germany, UK and Australia will be our three priority markets to launch our products,” he concluded. We will follow up regarding their Australian plans in future newsletters.

Pinion

One of the products getting most attention at Eurobike was the Pinion motor gearbox unit. Pinion has been making mid-mounted internal gearboxes for quite a few years but now they’ve added electric drive motors into a single unit.

It comes in nine and 12 speed options and has already been spec’d on a wide range of new bikes. I test rode the nine speed version. It changed gears easily and had plenty of torque, but was not quite as quiet or smooth as I’d expected, in particular for one gear change about half way through the range. As yet, Pinion do not have an Australian service centre. Pinion say that the only maintenance will be to change the oil once per year or 10,000 kilometres, whichever comes first.

Villiger Dynamic

With Pinion’s first combined motor and gearbox only recently getting into full production, I saw at least two competitors with prototypes of what they considered to be better versions of this concept.

This one from Villiger Dynamic combines a motor with a CVT (continuously variable transmission). In other words, instead of having say 12 gears, you have an infinite number of incremental ratios.

CVT’s for bicycles have already been around for years, with Enviolo being the best known example. But to the best of my knowledge, Villiger is the first to combine this with a motor into a mid drive unit.

The ratio spread (the difference between the lowest and highest gear) on Enviolo is 380% and on most derailleur bikes is about 500% (ie on a 1×12 drive if the smallest cog has 10 teeth and the largest has 50 teeth then it has a 500% spread).

Villiager is claiming a 1,000% ratio spread and a weight of 3.8 kg compared to Pinion’s 4.2 kg. It also has a reverse gear for cargo bikes and a ‘hold’ feature when stopped, including on a hill, similar to an automatic car.

It has a battery regeneration feature when decelerating, such as on descents.

The Villiger Dynamic is not yet in production. The company is a multi-generational family owned Swiss-based manufacturer that mainly makes agricultural products.

Tarran

Cargo bikes are still a very small market in Australia. But it’s a growing niche that is already well established in Europe. According to data presented at the show by ZIV the German bike industry association annual sales of cargo bikes in Germany last year totalled 235,000 units of which 189,000 were e-cargo and only 46,000 analogue bikes.

Clearly e-power has been the critical difference that enables these big, heavy bikes to be realistically ridden by people of all sizes, including women.

But when the bikes are stationery, they’re cumbersome to manoeuvre. Tarran has developed a ‘landing gear’ that is integrated with its central kickstand.

It electronically deploys at low speed to keep the bike stable, a bit like an aeroplane and like training wheels on a kids bike. It automatically raises once the rider starts again and gathers speed. As you can see from the closeup of the wheels, they hare multi-directional, meaning you can wheel the bike sideways in tight spaces, because they lift the front wheel off the ground.

The Tarran also features a radar based rear view system that shows approaching cars and warns the rider via vibrations to the handlebar grips. It has automatic turning lights and a camera to detect theft. The whole bike looked highly refined for a prototype.

The founder, who previously worked at another Eurobike debutant, DJI, said the Tarran will go into production at the end of 2024.